説明

基礎情報

| モデル番号。 | WNS2-1.25-YQ |

| 関数 | 蒸気ボイラー、石油ボイラー |

| 燃料 | ガス焚き |

| インストール | パッケージケトル |

| 構造 | フォイエロア |

| メディア | 蒸気と水 |

| 水の循環 | 強制循環 |

| ドラムの配置 | 横型ボイラー |

| プレッシャー | プレッシャー |

| 製造レベル | あ |

| 燃焼スタイル | チャンバー燃焼ボイラー |

| 使用 | 産業、家庭、車両、発電所 |

| 輸送パッケージ | 裸でラップを巻いて |

| 商標 | リーチ-ケッセル |

| 起源 | 中国 |

| HSコード | 8402190000 |

| 生産能力 | 5000トン/年 |

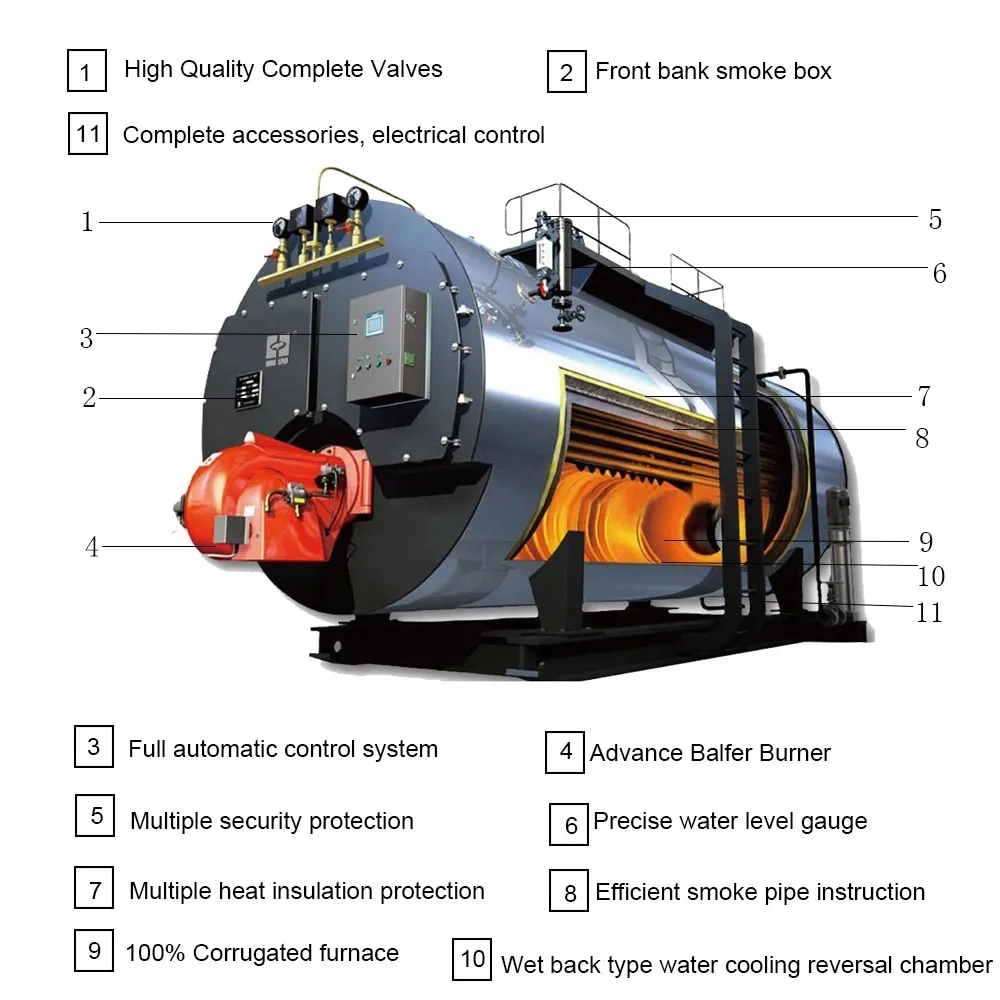

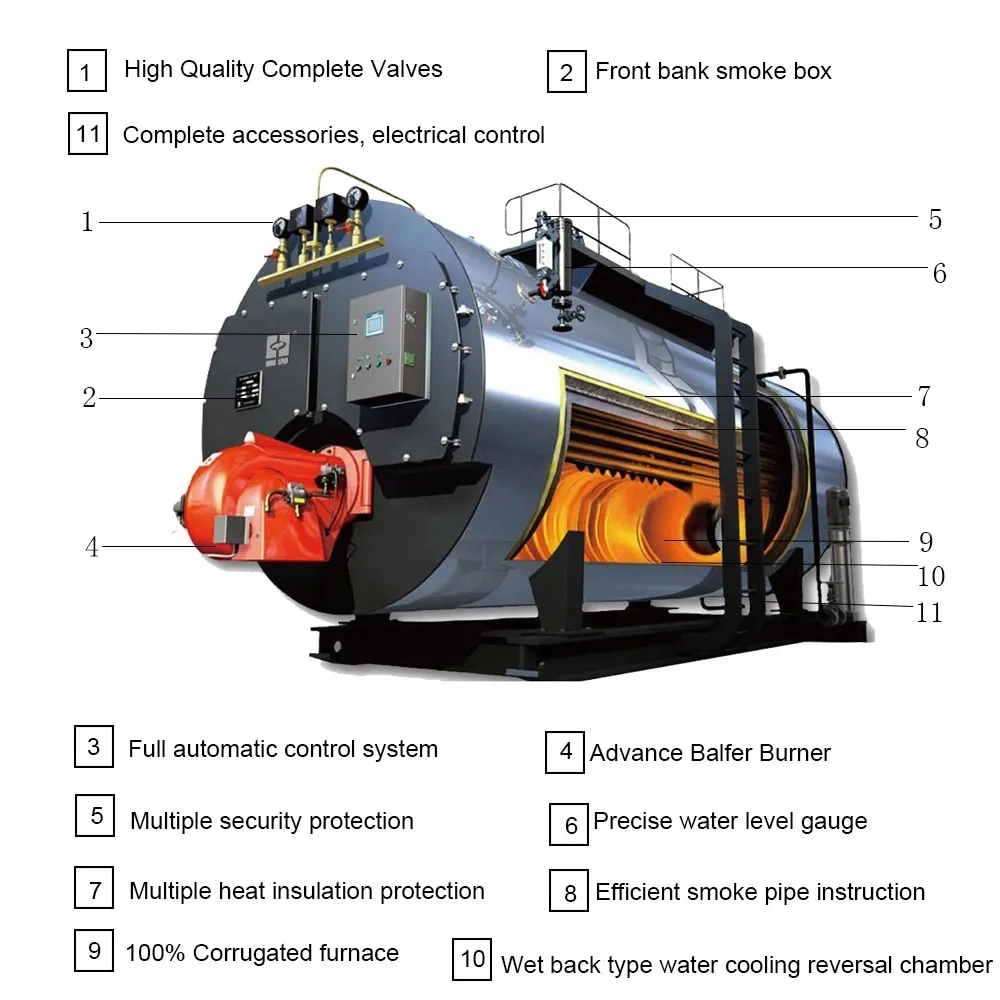

製品説明

主な特長: 1. 石油ボイラーは工業的にインテリジェントに設計されており、細部にまで配慮しているため、お客様の時間とコストの節約に役立ちます。 2. 独自の研究所を持ち、石油ボイラーのすべてのソリューションは実験データに基づいています。 3. 石油ボイラーは安全で環境に優しいです。 優しい省エネ商品4. 石油ボイラーに関する 24 時間年中無休のオンライン アドバイスを提供します。5. 石油ボイラー業界で 30 年以上の業界経験。6. カスタマイズされた石油ボイラー ソリューションは、業界とケースに基づいています。7. 適切な石油ボイラー ソリューションにより、設備の資本コストと運用コストを削減できます。

モデル番号。 | WNS0.5-1.0-Y/Q | WNS0.7-1.0-Y/Q | WNS1.0~1.0

/1,25-Y/Q | WNS1,5-1,0/1,25

-Y/Q | WNS2-1,25/1,6/2,5

-Y/Q | WNS3-1.25/1.6/2.5

-Y/Q | WNS4-1,25/1,6/2,5

-Y/Q | WNS5-1.25/1.6/2.5

-Y/Q |

定格蒸発量

(t/h) | 0,5 | 0,7 | 1 | 1.5 | 2 | 3 | 4 | 6 |

評価済み

プレッシャー

(MPa) | 1,0 | 1,0 | 1,0/1,25 | 1,0/1,25 | 1,25/1,6/2,5 | 1,25/1,6/2,5 | 1,25/1,6/2,5 | 1,25/1,6/2,5 |

ネンダンプ温度。 (℃) | 184 | 184 | 184/194 | 184/194 | 194/205/220 | 194/205/220 | 194/205/220 | 194/205/220 |

効率 | 93 % | 93 % | 93 % | | | | | |

| | | | | | | | |

| | | | | | | | |

| | | | | | | | |

| | | | | | | | |

| | | | | | | | |

| | | | | | |

Henan Reach Special Equipment is located in the central city of Zhengzhou, Henan Province, China. Our company is a professional trade supplier of industrial equipment such as boilers, with 12 production companies with various qualifications and over 30 employees. Mainly engaged in the design and sales of oil and gas steam boilers, coal/biomass steam boilers, oil and gas thermal oil boilers, coal/biomass thermal oil boilers, electric heating steam boilers, oil and gas hot water boilers, and medium and high temperature hot air furnaces. The manufacturers our company collaborates with are all legitimate production enterprises with A-level and B-level qualifications for Chinese boiler manufacturing. They have various certifications both domestically and internationally, including CE certification, ASME certification, etc., which can fully meet the matching requirements for boilers in various production environments in different countries. The factories our company collaborates with are all based on the manufacturing and production of various pressure vessels such as steam boilers, thermal oil boilers, and autoclaves. We have established an industrial system that integrates product development, engineering project design, equipment manufacturing, engineering installation, system debugging, pre-sales, sales, and after-sales services. Our company's products are not only sold and widely praised in the domestic market of China, but also exported to more than 60 countries and regions such as South Korea, Vietnam, Myanmar, Mongolia, the Philippines, and Indonesia, receiving recognition and pursuit from customers. I believe that our company can bring objective benefits to customers with advanced technology, excellent equipment, excellent products, and exquisite services. We look forward to long-term friendly cooperation with friends from various countries! Welcome to our store!Q1: What about after sales service, such as installation and commissioning?Answer:(1)English manual, drawings are supplied with boiler. (2)Engineers are able to instruct installing and commissioning abroad.Q2: What are the main products?Answer:(1)Oil fired steam boiler, capacity from 0.1t-20t (2) Gas fired steam boiler, capacity from 0.1-20t (3) Electric steam generator, capacity from 36kw-28800kwQ3: How to insure your product quality?Answer:(1)Strength calculation report with applied materials information; (2)100%NDT(non-destructive inspection) report of steel plate, tube and welding rod; (3)100% X-ray inspection(welding seam): ensure the quality of entire boiler; (4)Hydrostatic test: ensure the standard working pressure and safety; (5)Third-party inspection report; (6)Passed ISO, ASME certifications