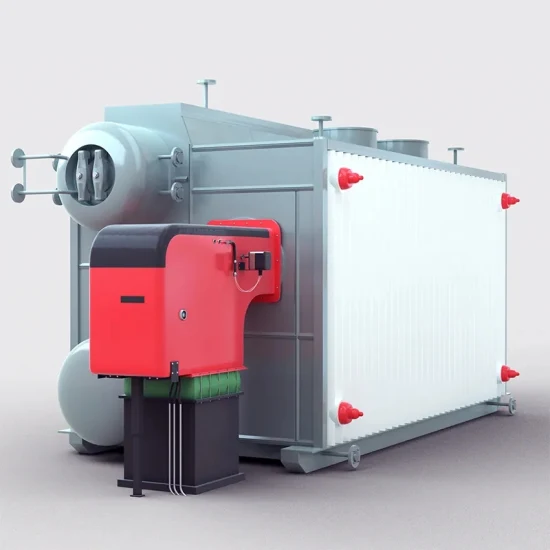

Szs ホット販売ダブルドラムステンレス鋼蒸気ボイラー石油ボイラー機産業機械用

主な特長 SZSシリーズボイラーは縦型二重ドラムとD型チャンバー構造を持ち、右側に炉、左側に対流管群と過熱器を配置しています。

お問い合わせを送信してください説明

基礎情報

| モデル番号。 | SZS10-1、25-Y。 Q SZS15-1,25-Y. Q SZS20-1,25-Y. Q |

| 関数 | 蒸気ボイラー、石油ボイラー |

| 燃料 | ガス焚き |

| インストール | パッケージケトル |

| 構造 | フォイエロア |

| メディア | 蒸気と水 |

| 水の循環 | 強制循環 |

| ドラムの配置 | 横型ボイラー |

| プレッシャー | プレッシャー |

| 製造レベル | あ |

| 燃焼スタイル | チャンバー燃焼ボイラー |

| 使用 | 産業、家庭、車両、発電所 |

| 輸送パッケージ | 裸でラップを巻いて |

| 商標 | リーチ-ケッセル |

| 起源 | 中国河南省 |

| HSコード | 8402190000 |

| 生産能力 | 5000トン/年 |

製品説明

主な特徴SZSシリーズボイラーは縦二重ドラムとD型チャンバー構造を備えています。 右側にオーブン、左側に対流管列が配置されており、対流管列の上にスーパーヒーターが配置されています。 本体は中央と両端の柔軟なサポートで地下に取り付けられており、ボイラーが水平方向に横に拡張することが保証されています。 炉の周囲には膜水冷管壁があります。 炉とチューブバンクは、炉の左側にある膜水チューブ冷却壁によって完全に分離されています。 束の後部はまばらな層構造を持ち、前部は整列した構造を持っています。 炉出口からの煙は後燃焼室、対流管バンク領域に入り、次に左前部からスパイラルエコノマイザーとファインコイルコンデンサーに入り、最終的に煙突を通って大気中に排出されます。

型式:ガス・石油焚き蒸気ボイラーSZS型

構造: WaterTube 3 パス

定格蒸気能力: 10-50 トン/時間

ネンダンプドルック: 1,25/1,6/2,5 MPa

温度: 194/205/220 °C

用途:繊維工場、食品・飲料、化学、医療、軽工業、ゴム、印刷・染色、製紙工場、木材加工、衣類・洗濯など。

モデル番号。 | SZS10-1,25-Y/QSZS10-1,6-Y/QSZS10-2,5-Y/Q | SZS15-1,25-Y/QSZS15-1,6-Y/QSZS15-2,5-Y/Q | SZS20-1,25-Y/QSZS20-1,6-Y/QSZS20-2,5-Y/Q | SZS25-1,25-Y/QSZS25-1,6-Y/QSZS25-2,5-Y/Q | SZS30-1,25-Y/QSZS30-1,6-Y/QSZS30-2,5-Y/Q | SZS35-1,25-Y/QSZS35-1,6-Y/QSZS35-2,5-Y/Q | SZS40-1,25-Y/QSZS40-1,6-Y/QSZS40-2,5-Y/Q |

ネンフェルダンプフング (T/h) | 10 | 15 | 20 | 25 | 30 | 35 | 40 |

ネンドラック (Mpa) | 1,25/1,6/2,5 | 1,25/1,6/2,5 | 1,25/1,6/2,5 | 1,25/1,6/2,5 | 1,25/1,6/2,5 | 1,25/1,6/2,5 | 1,25/1,6/2,5 |

ネンダンプ温度。 (℃) | |||||||

| 98 %/td> | 98 %/td> | 98 %/td> | 98 %/td> | 98 %/td> | 98 %/td> | 98 %/td> | |

Environmental protectionBig combustion chamber equipped with Low emission combustion burner effectively reduce the NOx to 30mg/m3. Smoke duct and smoke outlet use internal insulation to reduce operating noise.Combustion chamber uses full membrane water cooling wall structure and pressurized combustion without smoke mixture.Energy conservationGood quality alumina silicate fiber and fire clay insulation material are used and the boiler body temperature is controlled below 45ºC and greatly heat loss is reduced. Combustion chamber is designed with narrow distance tube membrane water cooling wall which has good air proof to reduce heat lost and increase boiler thermal efficiency. Internal inspection holes uses high-alumina refractory and manhole cover seal devices, solving superheat problem in this part caused by using refractory bricks.ConvenienceManholes are placed on the front and back side of drums and inspection doors on back side of boiler easy to open for inspection and clean inner and outer parts.Longer lifespanMembrane structure are used in the front and back wall for boiler body and highly increased their lifespan to over 20 years.The key processes including material cutting, rolling, drilling are done by advanced CNC machining process to reduce the assembly stress and extend boiler service lifetime.Flutter prevention fastener is used for high temperature part convection tubes, which avoid convection tube cracking problem.Longitudinal and girth joint adopt advanced automatic submerged-arc welding for good welding quality. All longitudinal and girth joint will be tested by radiographic inspection. Henan Reach Special Equipment is located in the central city of Zhengzhou, Henan Province, China. Our company is a professional trade supplier of industrial equipment such as boilers, with 12 production companies with various qualifications and over 30 employees. Mainly engaged in the design and sales of oil and gas steam boilers, coal/biomass steam boilers, oil and gas thermal oil boilers, coal/biomass thermal oil boilers, electric heating steam boilers, oil and gas hot water boilers, and medium and high temperature hot air furnaces. The manufacturers our company collaborates with are all legitimate production enterprises with A-level and B-level qualifications for Chinese boiler manufacturing. They have various certifications both domestically and internationally, including CE certification, ASME certification, etc., which can fully meet the matching requirements for boilers in various production environments in different countries. The factories our company collaborates with are all based on the manufacturing and production of various pressure vessels such as steam boilers, thermal oil boilers, and autoclaves. We have established an industrial system that integrates product development, engineering project design, equipment manufacturing, engineering installation, system debugging, pre-sales, sales, and after-sales services. Our company's products are not only sold and widely praised in the domestic market of China, but also exported to more than 60 countries and regions such as South Korea, Vietnam, Myanmar, Mongolia, the Philippines, and Indonesia, receiving recognition and pursuit from customers. I believe that our company can bring objective benefits to customers with advanced technology, excellent equipment, excellent products, and exquisite services. We look forward to long-term friendly cooperation with friends from various countries! Welcome to our store! Q1: What about after sales service, such as installation and commissioning?Answer:(1)English manual, drawings are supplied with boiler. (2)Engineers are able to instruct installing and commissioning abroad.Q2: What are the main products?Answer:(1)Oil fired steam boiler, capacity from 0.1t-20t (2) Gas fired steam boiler, capacity from 0.1-20t (3) Electric steam generator, capacity from 36kw-28800kwQ3: How to insure your product quality?Answer:(1)Strength calculation report with applied materials information; (2)100%NDT(non-destructive inspection) report of steel plate, tube and welding rod; (3)100% X-ray inspection(welding seam): ensure the quality of entire boiler; (4)Hydrostatic test: ensure the standard working pressure and safety; (5)Third-party inspection report; (6)Passed ISO, ASME certifications

Environmental protectionBig combustion chamber equipped with Low emission combustion burner effectively reduce the NOx to 30mg/m3. Smoke duct and smoke outlet use internal insulation to reduce operating noise.Combustion chamber uses full membrane water cooling wall structure and pressurized combustion without smoke mixture.Energy conservationGood quality alumina silicate fiber and fire clay insulation material are used and the boiler body temperature is controlled below 45ºC and greatly heat loss is reduced. Combustion chamber is designed with narrow distance tube membrane water cooling wall which has good air proof to reduce heat lost and increase boiler thermal efficiency. Internal inspection holes uses high-alumina refractory and manhole cover seal devices, solving superheat problem in this part caused by using refractory bricks.ConvenienceManholes are placed on the front and back side of drums and inspection doors on back side of boiler easy to open for inspection and clean inner and outer parts.Longer lifespanMembrane structure are used in the front and back wall for boiler body and highly increased their lifespan to over 20 years.The key processes including material cutting, rolling, drilling are done by advanced CNC machining process to reduce the assembly stress and extend boiler service lifetime.Flutter prevention fastener is used for high temperature part convection tubes, which avoid convection tube cracking problem.Longitudinal and girth joint adopt advanced automatic submerged-arc welding for good welding quality. All longitudinal and girth joint will be tested by radiographic inspection. Henan Reach Special Equipment is located in the central city of Zhengzhou, Henan Province, China. Our company is a professional trade supplier of industrial equipment such as boilers, with 12 production companies with various qualifications and over 30 employees. Mainly engaged in the design and sales of oil and gas steam boilers, coal/biomass steam boilers, oil and gas thermal oil boilers, coal/biomass thermal oil boilers, electric heating steam boilers, oil and gas hot water boilers, and medium and high temperature hot air furnaces. The manufacturers our company collaborates with are all legitimate production enterprises with A-level and B-level qualifications for Chinese boiler manufacturing. They have various certifications both domestically and internationally, including CE certification, ASME certification, etc., which can fully meet the matching requirements for boilers in various production environments in different countries. The factories our company collaborates with are all based on the manufacturing and production of various pressure vessels such as steam boilers, thermal oil boilers, and autoclaves. We have established an industrial system that integrates product development, engineering project design, equipment manufacturing, engineering installation, system debugging, pre-sales, sales, and after-sales services. Our company's products are not only sold and widely praised in the domestic market of China, but also exported to more than 60 countries and regions such as South Korea, Vietnam, Myanmar, Mongolia, the Philippines, and Indonesia, receiving recognition and pursuit from customers. I believe that our company can bring objective benefits to customers with advanced technology, excellent equipment, excellent products, and exquisite services. We look forward to long-term friendly cooperation with friends from various countries! Welcome to our store! Q1: What about after sales service, such as installation and commissioning?Answer:(1)English manual, drawings are supplied with boiler. (2)Engineers are able to instruct installing and commissioning abroad.Q2: What are the main products?Answer:(1)Oil fired steam boiler, capacity from 0.1t-20t (2) Gas fired steam boiler, capacity from 0.1-20t (3) Electric steam generator, capacity from 36kw-28800kwQ3: How to insure your product quality?Answer:(1)Strength calculation report with applied materials information; (2)100%NDT(non-destructive inspection) report of steel plate, tube and welding rod; (3)100% X-ray inspection(welding seam): ensure the quality of entire boiler; (4)Hydrostatic test: ensure the standard working pressure and safety; (5)Third-party inspection report; (6)Passed ISO, ASME certifications